H237DN-D Manual Load, Hydarulic Single Tube Double End Notching Machine

This manual load/unload system will accept our 237DNI inserts for notching rounds, squares, rectangles and special shapes of tubing and pipe up to 2” standard (2-3/8” OD x .154” wall). The unit will notch both walls of both tube ends in a single cycle. Along with standard 90º radius notches, custom configurations are possible.

The operator will manually load the tubes into a nesting area between the H237DN notching heads and depress the dual palm buttons to cycle the system. One head will move into position (approximately 4-1/2” – 5”) and cycle notching both ends of the tube. The notching head will now retract and the operator will manually remove the notched tube.

Features/Specifications:

- 2" Standard pipe (2-3/8" diameter x .154" wall) capacity

- 12" minimum to (consult factory) maximum part length capacity

- Manual load/unload

- Slide assembly for moving (1) notching head in and out

- Two H237DN hydraulic notching heads

- Spray mist part lubrication system

- Allen Bradley PLC

- 480 VAC, 3 phase, 60 Hz, 30 amp main control power required

- Two hydraulic power units each with a 5 HP motor, 20 gallon reservoir, 2500 PSI systems & air cooled heat exchanger

- Pneumatic requirements, 80 PSI at 3 CFM

- Dual palm button activated

- Operation's manual

- Approximate machine cycle time of 4 - 6 seconds

H237DN-D

H237DN-D Automatic Load, Hydraulic Double End Notching System

This fully automatic system will accept our 237DNI inserts for notching tubing or pipe up to 2” Standard (2-3/8” OD X .154” wall). A hopper fed system, will notch both walls of both tube ends of a single tube each cycle. Along with standard 90º radius notches, custom configurations are possible.

An operator will load a bundle of tubes into the hopper holding approximately 250 tubes. The tubes are then fed into a magazine for loading into the clamp station. Once in location the tube is clamped in position, the notching heads are shuttled in and then the notching heads cycle simultaneously completing the notching operation. Upon completion of this cycle, the tube is unclamped and discharged onto an inclined run off ramp. Customer is responsible for means of collecting notched tubes from ramp.

Features/Specifications:

- 2” Standard pipe (2-3/8” OD x .154” wall) capacity

- 12" minimum to (consult factory) maximum part length capacity

- Automatic load/unload

- Hopper conveyor holding approximately 250 tubes

- Magazine holding approximately 15 tubes

- Transfer & clamping assembly of tubes is notching station

- Slide assemblies for moving both notching heads in and out

- Two H237DN hydraulic notch heads

- Spray mist part lubrication system

- Allen Bradley PLC

- 480 VAC, 3 phase, 60 Hz, 30-60 amp main control power required

- Two hydraulic power units each with a 10 HP motor, 60 gallon reservoir, 2500 PSI systems & air cooled heat exchanger

- Pneumatic requirements, 80 PSI at 3 CFM

- Operation's manual

- Approximate machine rate of 1200 tubes per hour

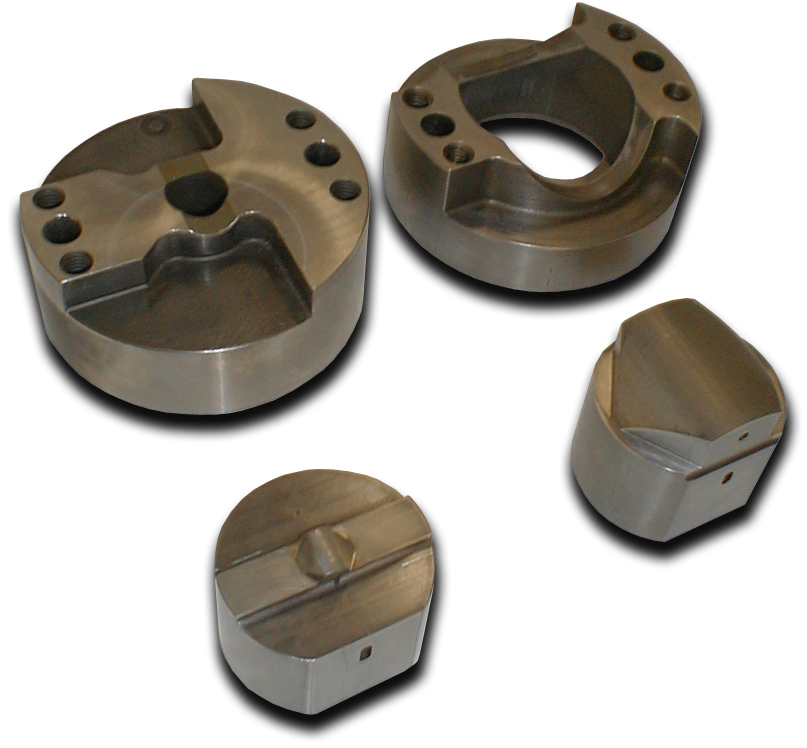

237DNI Double Notch Inserts

These inserts are manufactured to the specific application notching both walls of a single tube end per press stroke. Cutting members are manufactured of hardened D-2 tool steel for maximum tool life and are easily removed for sharpening purposes. Includes air blast to assist slug removal, where applicable. Unique tool design utilizes fixed positioning of inserts minimizing tool changeover time.

Inserts can be manufactured for conventional notching of tubes to fit another tube of equal or different diameter for 90° joints. Can also be used to produce slots, v-notches, and many other configurations on tube ends within the capacity of the unit.

237DNI